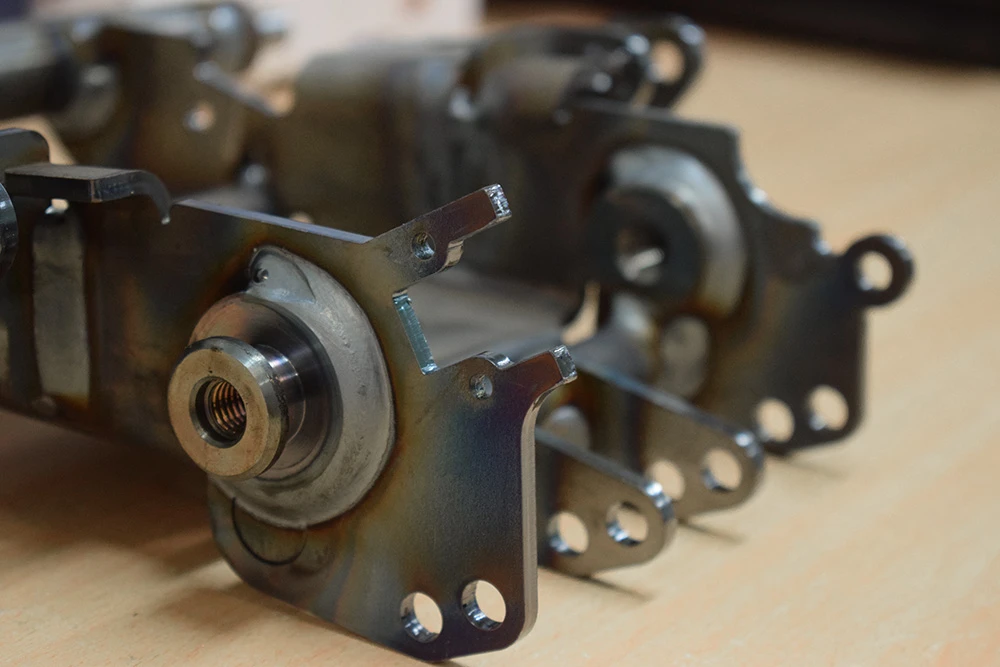

At Be-Ge Plåtindustri AB our manufacturing and production comprises of a very modern topic section where the components are cut out by laser or punched out.

– Unalloyed steel from 0,5 to 25 mm

– Stainless and acidproof steel from 0,5 to 15 mm

– Aluminum from 0,5 to 8 mm

– Coppar and copper alloys from 0,5 to 8 mm

In the smaller range, 0,5 to 8,0 mm, it is mainly a combined punching and laser machine used. It can also do threading, stamping and forming. The bending press brakes are used with forces up to 220 tons, maximum length that can be bents is 4000 mm.

We also work with tool bounds forming and has the presses with forces up to 250 tons.

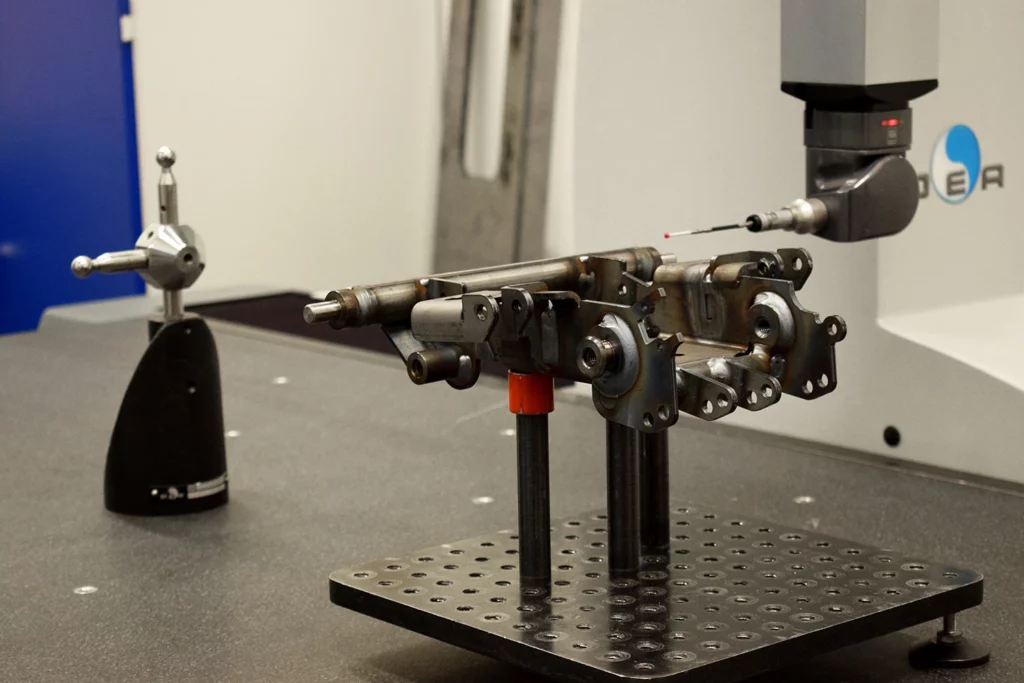

We have dedicated employees with long experience and broad expertise and efficient and mordern machinery. Together, this makes it possible to tailor the optimal product solutions to our customers needs.

The Be-Ge Group is a family-owned group of companies with operations in Sweden, Denmark, United Kingdom, Lithuania, The Netherlands and Germany. The Group comprises of several business areas such as Be-Ge Seating division, Be-Ge Component Division and Be-Ge Vehicle Division.

© Copyright Be-Ge Group 2025

We see that you are using Internet Explorer or Edge as your browser. Parts of this website will therefore not be displayed correctly. For the best experience, we recommend that you instead use Google Chrome or Mozilla Firefox.

| Kaka | Varaktighet | Beskrivning |

|---|---|---|

| _grecaptcha | Session | Används för att bekämpa spam i våra formulär.

Avsändare: google.com Företag: Google Analytics, Google |

| cli_user_preference | 1 dag | Denna cookie används för att identifera vilka cookies användaren har samtyckt till. |

| cookielawinfo-checkbox-analytics | 1 dag | Denna cookie används för att identifiera om användaren har samtyckt till att låtas spåras. |

| cookielawinfo-checkbox-necessary | 1 dag | Denna cookie används för att identifera vilka cookies användaren har samtyckt till. |

| CookieLawInfoConsent | 1 dag | Denna cookie sätts när användaren har samtyckt till användningen av cookies. |

| viewed_cookie_policy | 1 dag | Denna cookie används för att se om användaren har samtyckt till användningen av cookies eller inte. |

| Kaka | Varaktighet | Beskrivning |

|---|---|---|

| _ga | 2 år | Används för att skilja mellan besökare.

Avsändare: Be-Ge Företag: Google Analytics, Google |

| _ga_* | 2 år | Används för att bevara sessionens status. Avsändare: Be-Ge Företag: Google Analytics, Google |